Automated Truck Wash Systems

From the initial setup at your location to on-going support, we provide personalized attention to keep your fleet washing operations running seamlessly. Trust us to be your reliable partner in achieving efficient and effective automated washing solutions.

TYPES OF AUTOMATED WASH SYSTEMS

Private Fleet Wash: Tailored for Your Fleet Only

If your goal is to reduce fleet maintenance costs and streamline your fleet washing operation…

Every fleet out there is slightly different – so we consult with you first to find out what your fleet specifically needs. Using the best equipment, we design a wash system based on the ideal solution for your trucks. From efficient wash systems to high-quality chemicals, we’ll work with you to customize a solution that maximizes your fleet’s cleanliness while minimizing costs.

Commercial Truck Wash Business: Open To the Public

If your goal is to start a new business by opening a profitable automated truck wash…

Discover our comprehensive range of commercial truck wash equipment and chemical solutions designed for businesses looking to open a public truck wash. Give us a call to learn more about our commercial systems – from a quick express wash to full bells & whistles, we’ll work with you to find the best design for your business strategy.

Our Solutions

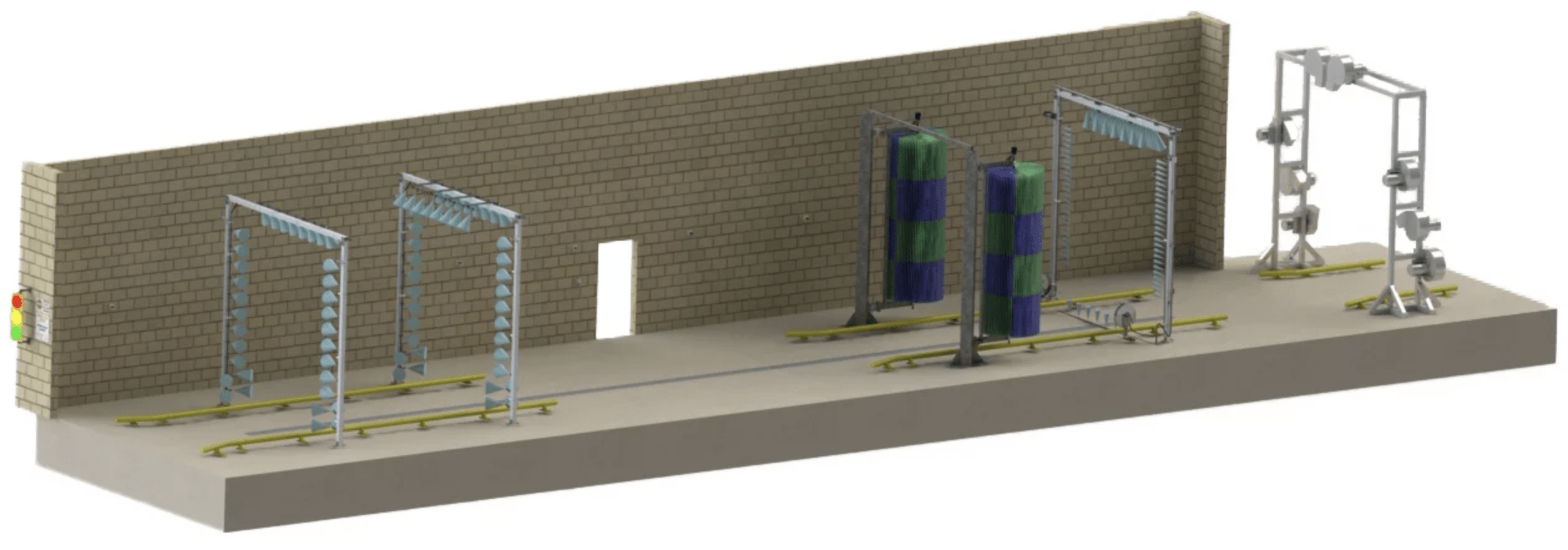

A Wide-Range of Automated Systems

This Department of Public Works saved over $60k after installing a touchless automated wash system

Here’s how one organization cut down their maintenance costs, significantly reduced downtime, and improved their fleet maintenance ROI with their investment in a 2-step automated wash system.

Get the full case study to find out how an automated wash system from Hydro-Chem Systems saved this Michigan Department of Public Works thousands of dollars in maintenance costs.

This School reduced the time spent washing to less than 2 minutes a bus

Discover how this School Bus Fleet revolutionized their bus wash operations, saving time, enhancing the quality of the cleaning, and increasing the longevity of their fleet.

Get the full case study to learn how an automated wash system and quality chemicals from Hydro-Chem Systems transformed their maintenance process, ensuring thorough cleaning and reducing the risk of rust and corrosion.

Truck and Fleet Wash Systems

We work hard to provide the best automatic truck wash solution for your specific situation!

We are the manufacturer of the automated truck wash equipment and the fleet cleaning detergents. Being the truck wash manufacturer allows us to customize your wash system to best fit your needs. Since we also manufacture fleet cleaning detergents, you’ll get a holistic fleet washing solution that works best for you. Whether your goal is simple or more complex, we find the best solution for you.

Common Questions

Why does your fleet need an automated truck wash?

- It reduces maintenance costs and extends the life of the vehicle.

- People trust a company that looks professional and clean.

- Drivers become easier to recruit and retain when they drive clean, well-maintained trucks.

- An automated fleet truck wash system is faster and more efficient than paying an employee or an outside company to clean your vehicles.

- A truck that is clean and maintained on the outside can reduce DOT inspections and costly delays.

Why choose Hydro-Chem Systems for your automated truck wash?

- Hydro-Chem Systems has been in business for almost 50 years! We have extensive experience with many automated vehicle wash systems; from the basic school bus wash to the extensive public commercial truck wash to everyone’s favorite 18 wheeler truck wash, we’ve done them all.

- Each large vehicle wash is custom manufactured and tailored to the individual client’s desires – from a very basic truck wash to having all the bells and whistles – we understand and design our wash to your needs.

- We strive to achieve the lowest cost-per-wash possible while still attaining the ultimate goal of a CLEAN vehicle

- We remove many of the unnecessary moving parts, reducing the chance of parts breaking down or wearing out too quickly to provide you with low maintenance costs for your wash equipment.

- We are the manufacturer of both the fleet wash equipment and the truck wash soaps so we know EXACTLY how they work together, giving us the ability to provide your fleet with the best clean.

What are the most important factors for using an automated truck wash?

Water Quality

Soft water is a must — washing with hard water will force you to use a stronger soap at a higher concentration.

Water Temperature

Using warm water to apply soap will allow you to use less soap at a lower concentration with shorter dwell time.

Detergent

The detergent choice must be tailored to the conditions of the wash, the vehicles, and cleanliness goals.

Application

The ability to apply the soap evenly and thoroughly will allow for a proper clean no matter the size or shape of the vehicle.

Dwell Time

The period of time that the truck wash soap sits on the vehicle to break down the road film and dirt.

High Pressure Rinse

Using different spinners at different angles, the high pressure rinse manifold is able to thoroughly rinse all surfaces of the vehicles including the sides, wheels, and chassis.